Jigs & Fixtures For The Hand Tool Woodworker Pdf Download UPDATED

Jigs & Fixtures For The Hand Tool Woodworker Pdf Download

Jigs and fixtures are used to make manufacturing and assembly processes simpler and more reliable, reducing cycle times and improving worker safety.

Typically, manufacturers machine tooling in metal, either in-firm or through outsourced vendors. Depending on the forces experienced by the part, all the same, it may not always be necessary to produce these tools in metallic.

Stereolithography (SLA) 3D printing materials accept advanced significantly, and there are a number of functional resins well suited to 3D printing jigs and fixtures, including Formlabs Standard Resins and Formlabs Engineering Resins. Manufacturers around the world accept used these materials to replace metal fixtures in automated machining operations, electronics assembly lines, foundries, and other production facilities.

Custom 3D printed jigs in-use for motorcycle gear manufacturing at Pankl Racing Systems.

Read on for seven specific examples of jigs and fixtures that can be 3D printed for some ideas to start implementing 3D printing on your production line.

This blog post is an excerpt from our white paper, Designing 3D Printed Jigs and Fixtures. Download the full white paper for a comprehensive look at jig and fixture design nuts, best practices for designing 3D printed jigs and fixtures, and tips for validating printed fixtures.

Download the White Paper: Designing 3D Printed Jigs and Fixtures

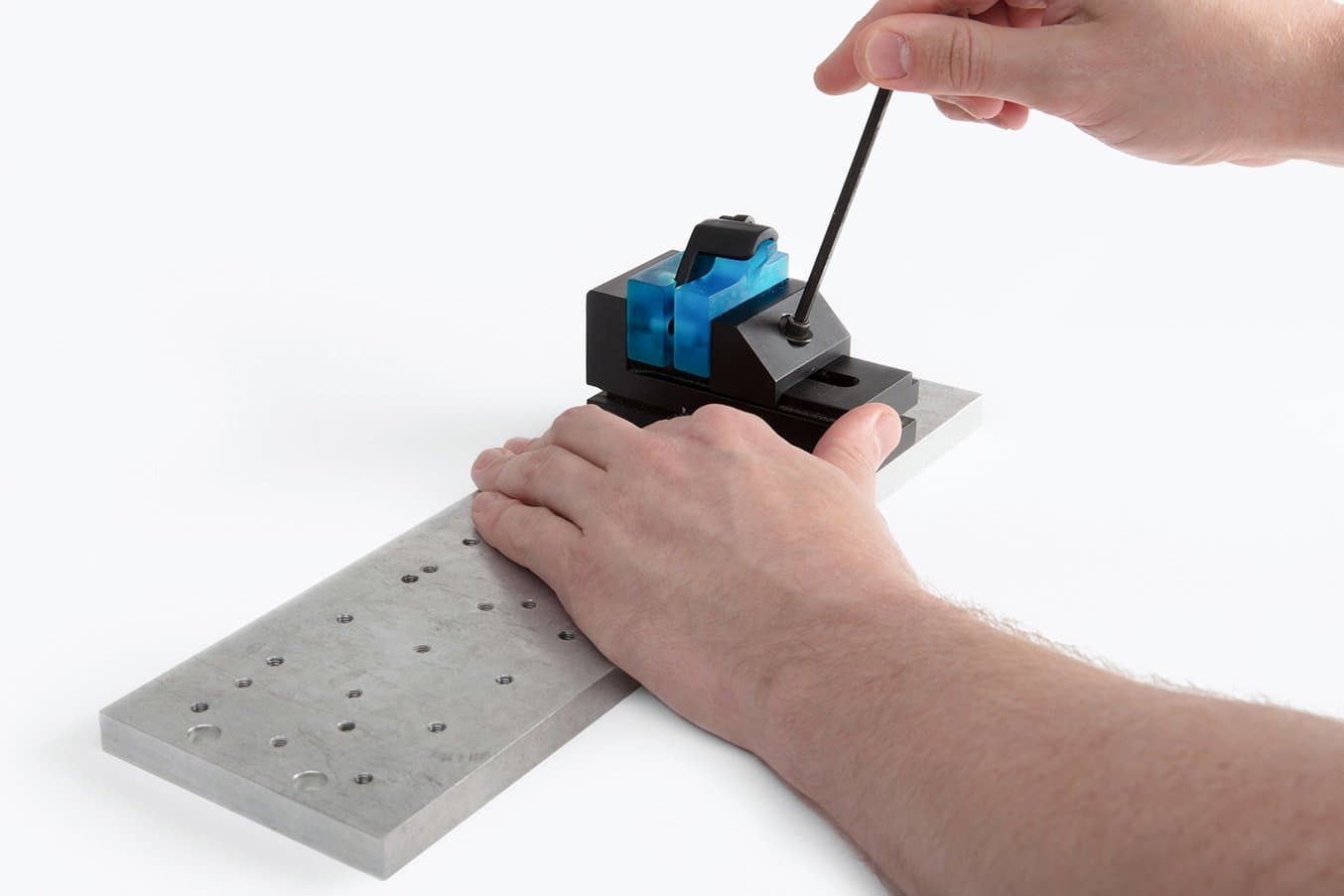

Soft jaw inserts are customized to closely match the unique geometry of a particular role, allowing for workholding of more than complex parts and preventing marring of softer metal or plastic parts. 3D printing in a fabric like Formlabs Tough Resin works well for producing soft jaw inserts and jigs considering of the quick build speed and low fabrication cost for dealing with complex shapes.

A part beingness clamped betwixt soft jaw inserts, printed in Formlabs Tough Resin.

Drill guides help prevent a drill bit from deflecting or wandering, maintaining angular and cylindrical tolerance requirements.

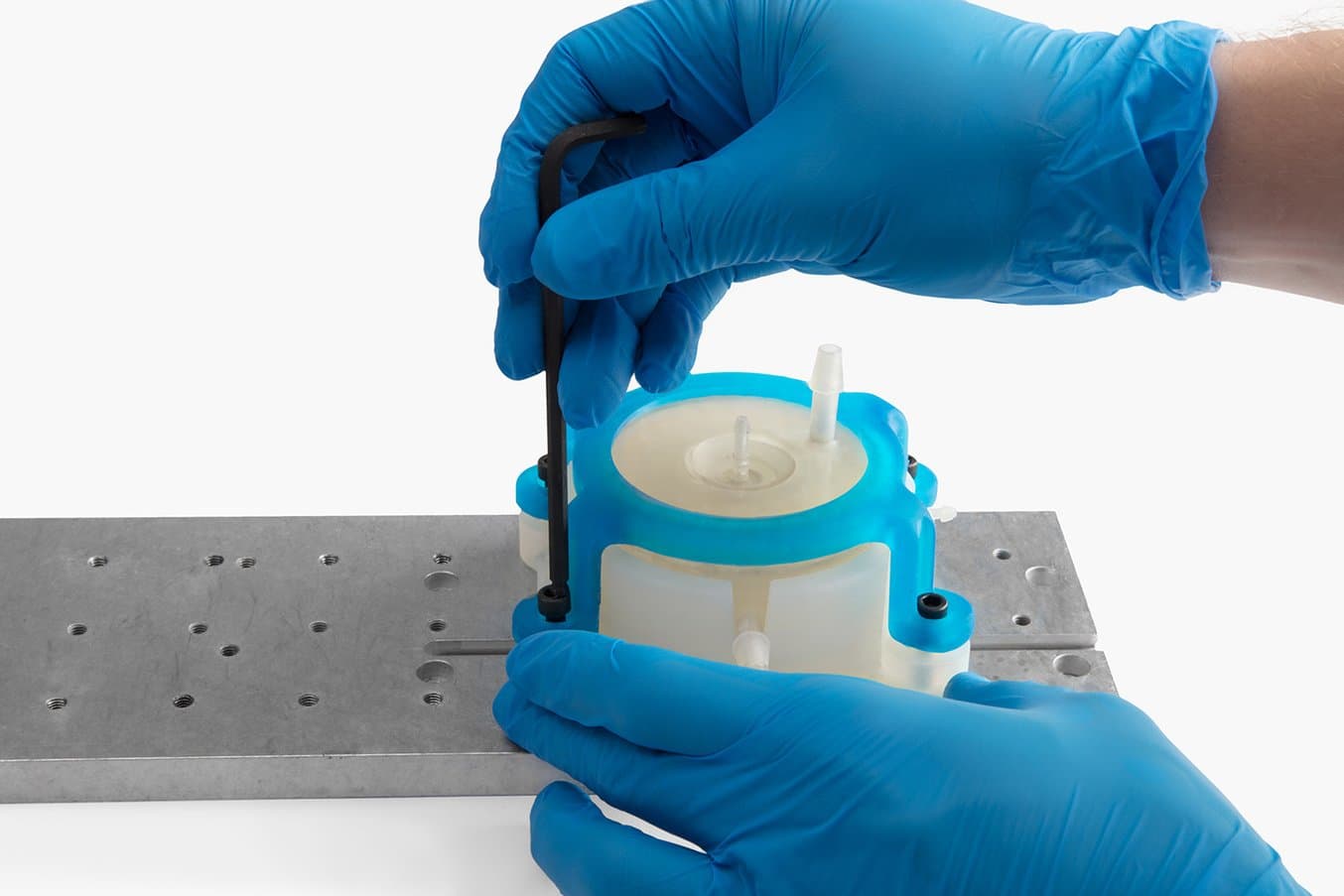

A press fit bushing in a drill jig, printed in Formlabs Tough Resin.

Drill guide bushings come in press fit or screw-in varieties, and can be purchased from industrial suppliers like McMaster-Carr. Bushings that have been designed specifically for utilize in plastics work best for SLA-printed jigs.

Utilize the tolerancing guidelines from our Applied science Fit White Paper to make up one's mind correct hole sizing for press plumbing equipment.

A simple tolerance check using a template or gauge tin quickly help a quality command inspector determine whether a function will piece of work for its end use. 3D printed get/no go gauges are useful when the part's successful part is determined by small-scale differences in form and dimension, and those dimensions can't hands or rapidly be assessed using calipers, micrometers, or other standard metrology tools, as in the case of complex rubber parts.

A go/no go gauge for inspecting a rubber gasket, printed in Formlabs Clear Resin.

Go/no get gauges are a fast, low-toll style to implement additional quality control checks for an associates or manufacturing line.

Tip: In certain applications, gauges can wear over time, leading to QC failures. Considering of their low price and ease of industry, 3D printed gauges can be hands reprinted and replaced on a predetermined schedule or as needed, to forbid quality drift from worn out gauges. This is most pronounced where the parts that are contacting the go/no go gauge are difficult metals.

For many products, connecting parts and adding fasteners to create subassemblies or full assemblies is the about labor intensive function of the manufacturing procedure. 3D printing part-specific associates jigs reduces bicycle times, improves ergonomic workflow for associates technicians, and improves consistency across production units.

An associates jig used for manufacturing the Formlabs Class 2 3D printer.

Disassembly is required to examine a production that has failed inspection, right an fault, or admission a device for refurbishment and repair. Using a disassembly jig makes this procedure faster and reduces the take a chance of breakage. For instance, separating an enclosure with snap fits requires each of the snaps to open simultaneously to prevent damage to the parts.

Disassembly jig for separating a snap-fit enclosure in Formlabs White Resin.

The depression toll of 3D printed bonding jigs makes regular replacement of these parts more adequate compared to jigs machined from plastic or metallic. In theory, bonding jigs and fixtures are designed well and maintained so they don't have to exist resurfaced or thrown out. In practice, it depends a lot on the labor and piece of work culture of a shop.

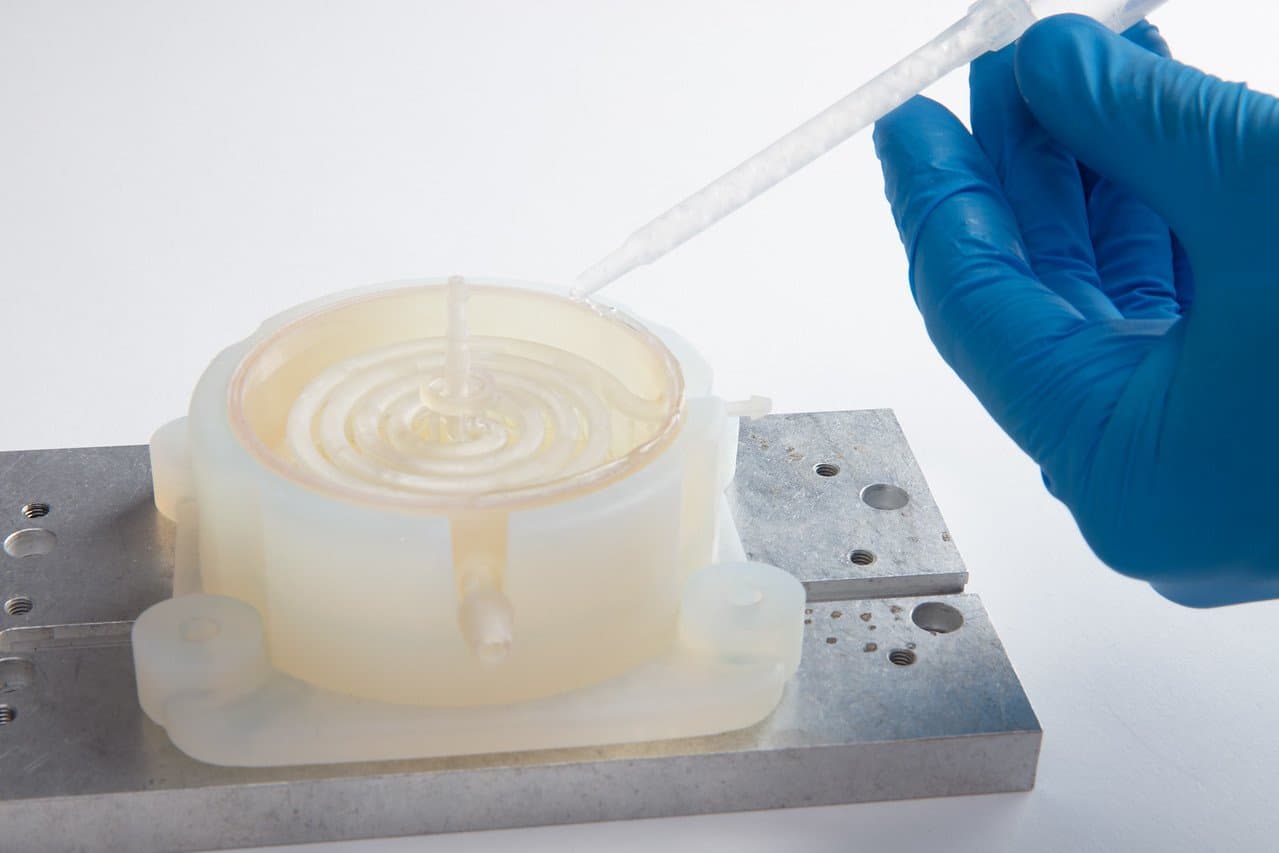

Agglutinative being applied to a function in a bonding jig printed in Formlabs Durable Resin.

Tip: Coating a bonding jig with a release agent volition make it easier to clean up whatsoever solidified adhesive that may spill onto the jig.

3D printed jigs are useful for depression-strength applications; for example, making sure a label is placed in the exact same location across multiple units or masking on an surface area for marking.

Using Formlabs Flexible Resin, a conformal masking template can be designed to perfectly match the role surface. For applications where a stiffer template is required, Durable Resin works well.

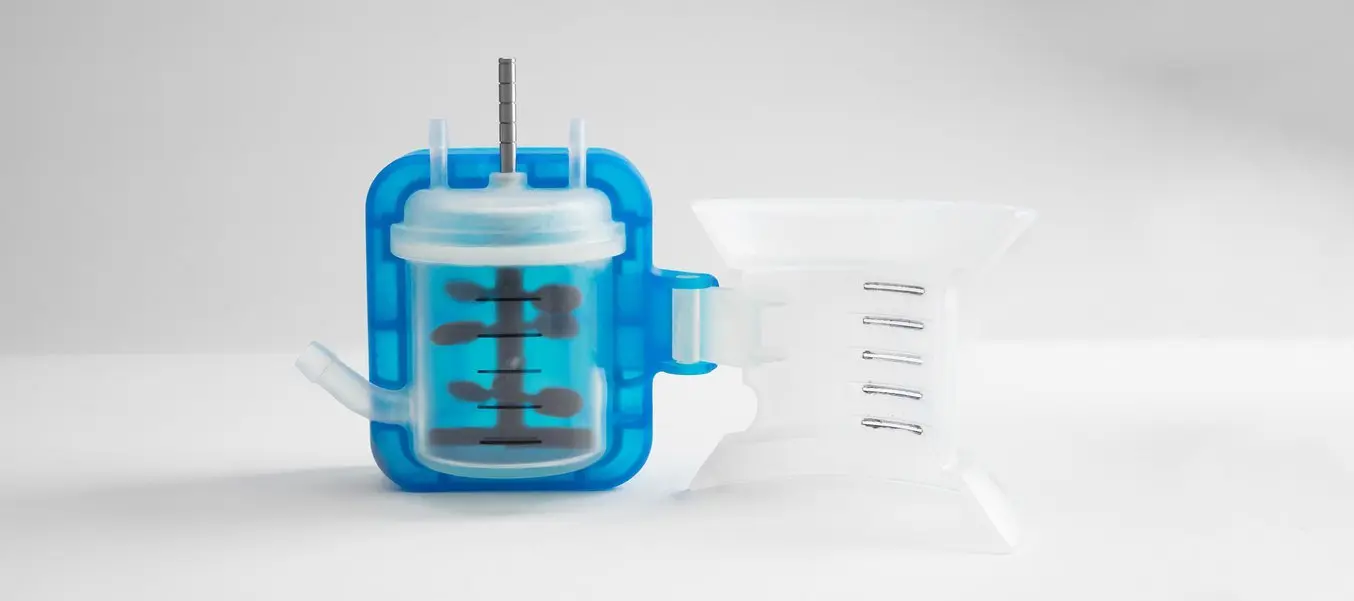

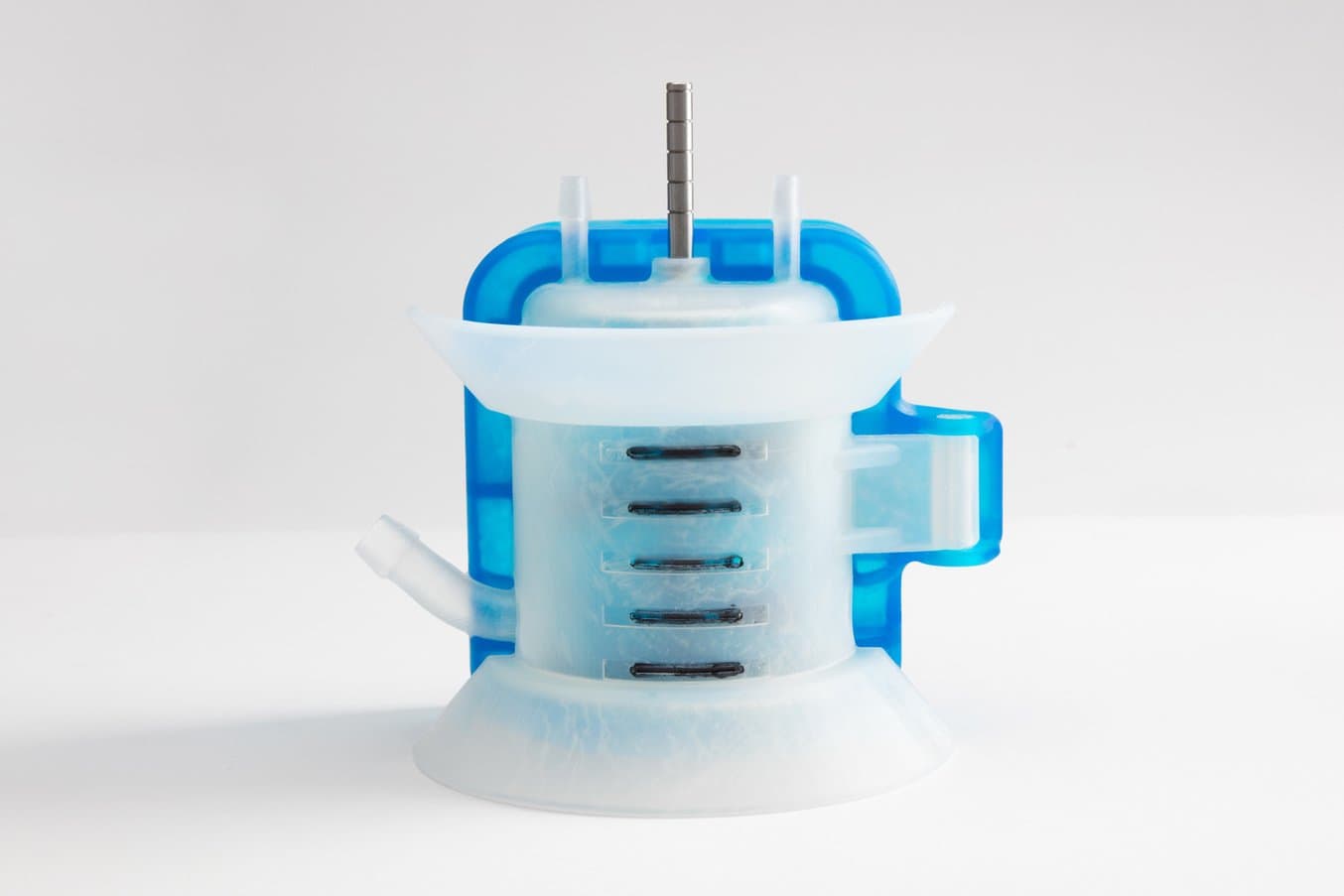

Hinged jig for applying volumetric markings, printed with Formlabs Tough Resin and Durable Resin.

While not a fixture or jig per se, surrogate parts are commonly used to exam fixtures or jigs in advance of last production parts, so that manufacturing and assembly lines can come online faster and iron out process kinks before the pressures of production are in identify.

Surrogate parts allow manufacturing procedure validation with low-cost 3D prints instead of risking delicate high value components like electronics assemblies.

SLA prints piece of work well for surrogate parts considering of their high dimensional accuracy and power to replicate fine features relevant for solving manufacturing or usability aspects that fused deposition modeling (FDM) or other print processes may miss. Additionally, since SLA printed parts are highly isotropic, they will behave more than similarly to their injection molded counterparts than anisotropic FDM parts.

Larn how Google ATAP used surrogate parts printed in Formlabs Loftier Temp Resin and reduced turnaround fourth dimension for a crucial component by 85% while saving over $100,000.

Download the full 20-folio white paper to learn the principles behind creating effective jigs and fixtures, with an emphasis on how to leverage 3D press to reduce costs, shorten development fourth dimension, and create more than efficient production workflows from design engineer to manufacturing floor technician.

White Paper Download: Designing 3D Printed Jigs and Fixtures

DOWNLOAD HERE

Posted by: ecksteinfirldetel.blogspot.com

Post a Comment for "Jigs & Fixtures For The Hand Tool Woodworker Pdf Download UPDATED"